Spoilboard surfacing and improving suction on a vacuum table

If you are considering the addition of a CNC router to your workshop, there is no question that learning how to use the machine effectively will take time. When it comes to learning the components of your machine and how to use it safely, the spoilboard cannot be overlooked. But what is a spoilboard anyways?

If you are considering the addition of a CNC router to your workshop, there is no question that learning how to use the machine effectively will take time. When it comes to learning the components of your machine and how to use it safely, the spoilboard cannot be overlooked. But what is a spoilboard anyways?

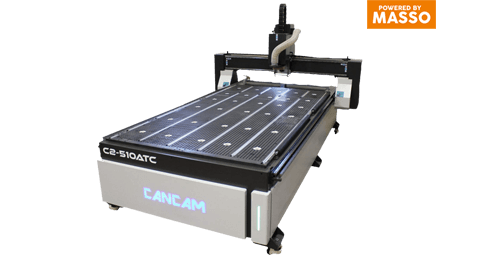

At CanCam, we are proud to be your premier source for commercial CNC machines for sale in Canada. We know that starting your own CNC machine shop can come with a bit of a learning curve. In this post, we explore the basics of spoil boards and vacuum tables to help you feel more informed about the equipment in your shop. If you are looking for high-quality CNC routers for home business or small shops, we have the equipment you need.

See our posts, Maximize Profits: How to Set Up and Run a Successful CNC Machine Shop and How Much Does a Metal CNC Machine Cost? How to Choose a Metal CNC Machine That Fits Your Budget and Operational Needs, for more information on selecting the right equipment for your shop.

What is a Spoilboard?

A spoil board, often referred to as a sacrificial board, is typically a 3/4” thick board that is placed on a vacuum table to protect the table when cutting through a substrate or workpiece. When a CNC vacuum pump is connected to the vacuum table, air is continuously pulled through the spoil board. This creates a vacuum under the spoil board and a very low-pressure area on top of the spoil board. When a part is laid on top of the low-pressure area, the pressure on the underside is less than on top, so the part is held in place.

Using a CNC router spoilboard typically works without the need for seals between the part and spoil board, which can simplify your processes. Spoil boards are commonly made of MDF, as it is a permeable sawdust and resin substrate that lets air pass through its entire surface. Since MDF is made of sawdust and resin, using different proportions or using sawdust from different wood species may affect the permeability of the material. It is important to have an understanding of how to use your machine effectively to ensure optimal results.

What is a CNC Vacuum Table?

A CNC vacuum table, sometimes referred to as a vacuum bed for CNC, is a specialized type of work holding system that is used with CNC routers to secure workpieces during machining processes. A CNC router vacuum table uses vacuum pressure to hold materials in place, offering several advantages, especially for working with thin or flexible materials that might be difficult to secure with traditional clamping methods. It is important to note that spoil board is used in conjunction with a vacuum table.

At CanCam, we pair our rotary vane vacuum pumps with our vacuum tables. These consist of an electric direct drive motor to the vacuum pump impeller which is made up of self-lubricating carbon vanes. The vanes rotate in the pump housing, drawing air in the inlet and discharging the air through the exhaust to create a vacuum. The increased vacuum results in superior hold-down capability and is ideal for wood, plastic, and other nonporous sheet-like materials. Contact a member of our team for support with choosing the appropriate type of equipment for your workshop.

How to Surface an MDF Spoilboard

MDF spoil boards need to be surfaced to remove the manufacturer-applied sealer to make it porous so the vacuum can operate at the highest efficiency and hold down the workpiece securely. Use the following steps to surface your MDF spoilboard. As always, our team of experts is always available to support you with troubleshooting any concerns you may have.

Start with 3/4″ medium density fiberboard (MDF).

Using a 4″ fly cutter with three blades, you should be spinning at 12,000 rpm at 30 meters per minute; using a 3″ fly cutter at 12,000 rpm, run at 25 meters per minute. Overlap each cut by about 1 mm

Take at least 0.5mm off both sides to remove the sealer that comes on all MDF boards.

Seal the four edges of your spoil board by either edge banding or using a sealer (e.g. epoxy or rubberized paint) on all four sides to seal the edges for an even and maximized vacuum. This will improve suction on a vacuum table.

At CanCam, we are dedicated to helping you find the equipment you need to boost the productivity and quality of your workshop. Learn more about our range of high-quality CNC machines by exploring our product lineup. We are pleased to provide free demos to help you feel confident about your purchase.