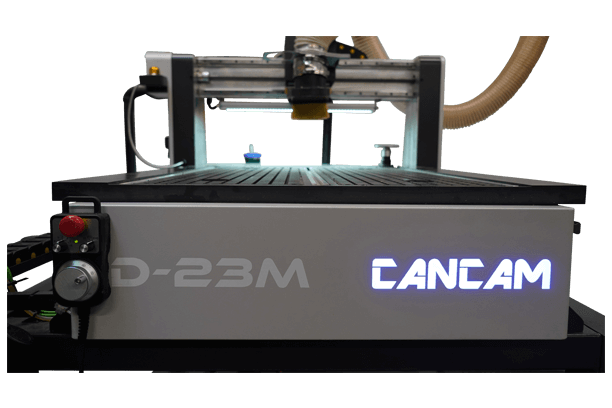

D-23M

D-23M 2x3' CNC Router

D-23M

D-23M 2x3' CNC Router

$11,100.00

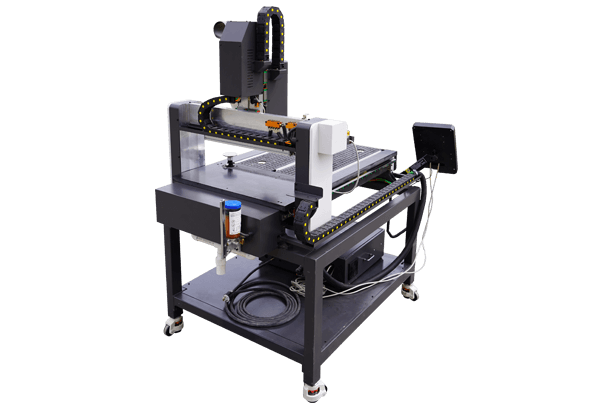

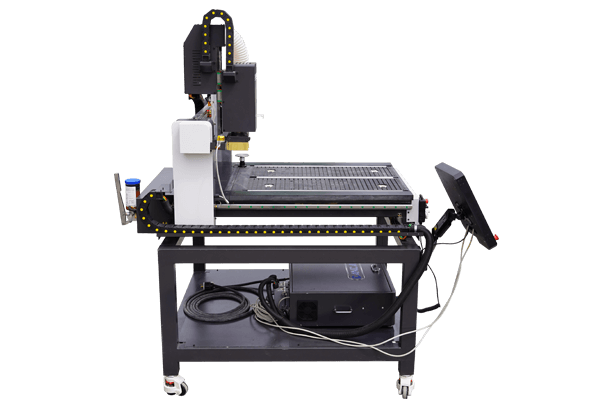

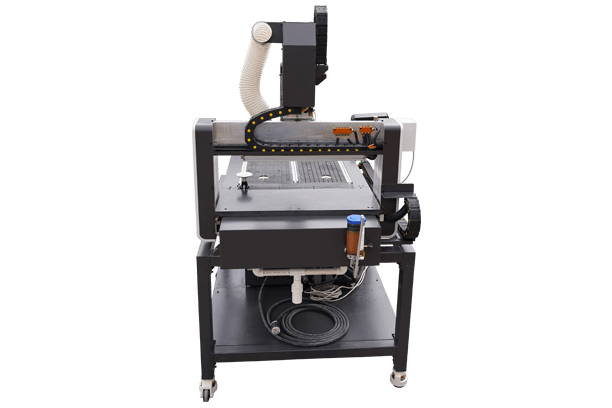

The D Series CNC routers are robustly engineered for light to medium-duty production applications, prototyping, wood and plastic engraving and cutting, and non-ferrous metal engraving and cutting, all at an impressive price point.

- Light Assembly Required: Some light assembly is required for the legs.

- Unique Build: Unlike traditional models that use steel tubes, the D-23M features a gantry made of billeted aluminum and a frame made of solid cast iron. This one-piece design for two major components ensures extreme rigidity and durability.

- Premium Components: All D-23M CNC routers are equipped with a 3HP spindle, leadshine motors, high-quality electrical components, electronic actuators for vacuum zones, TBI ballscrews and a Masso controller.

GTIN: 601570242267

Item related to this Product

-

$2,829.00

$2,829.00 -

$4,044.00

$4,044.00 -

$1375

$1375 -

$1450

$1450 -

$420

$420 -

$279.99

$279.99 -

$9

$9 -

$2,800.00

$2,800.00 -

$3,450.00

$3,450.00 -

$900

$900 -

$2000

$2000 -

$1050

$1050 -

$1550

$1550 -

$420

$420 -

$420

$420 -

$420

$420 -

$420

$420 -

$9

$9

Description

The spindle speeds can reach up to 24,000 RPM, with an IPM feed rate of up to 400 IPM. This ensures an ideal finish on your material of choice, while minimizing cutting time. Reduced cutting time allows you to complete jobs faster, thus maximizing your output.

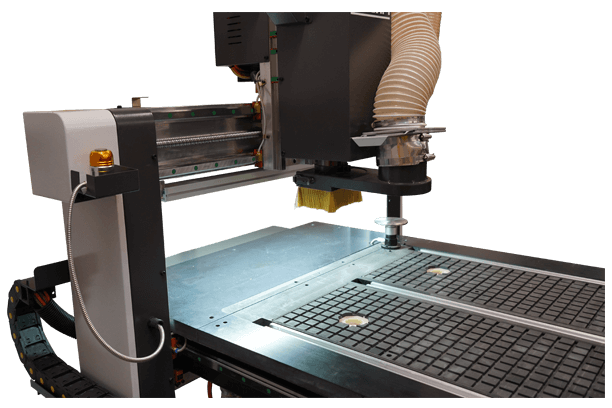

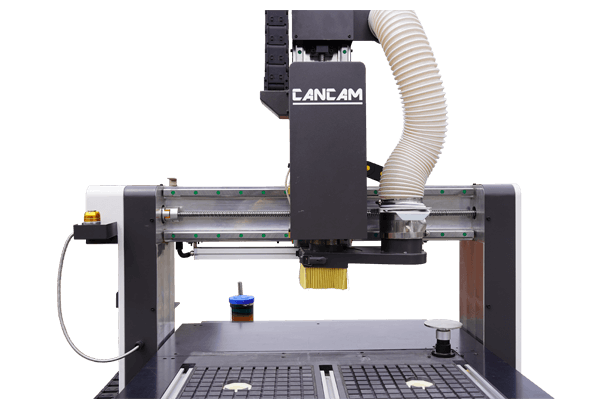

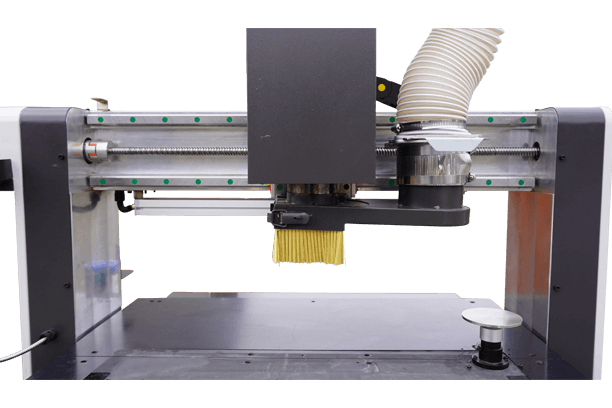

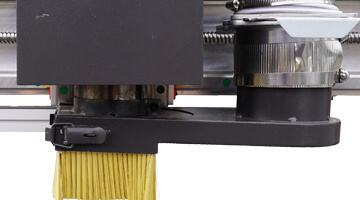

The D-23M 2×3’ CNC router is equipped with an ER20 collet spindle, allowing the use of up to ½-inch wide tool shanks. It features leadshine stepper motors, Hiwin linear rail guides, a fixed tool calibrator, mobile tool calibrator, and precision ballscrews on all axes. This makes the D-23M a robustly built, compact machine that delivers excellent cutting and engraving results.

Product Features

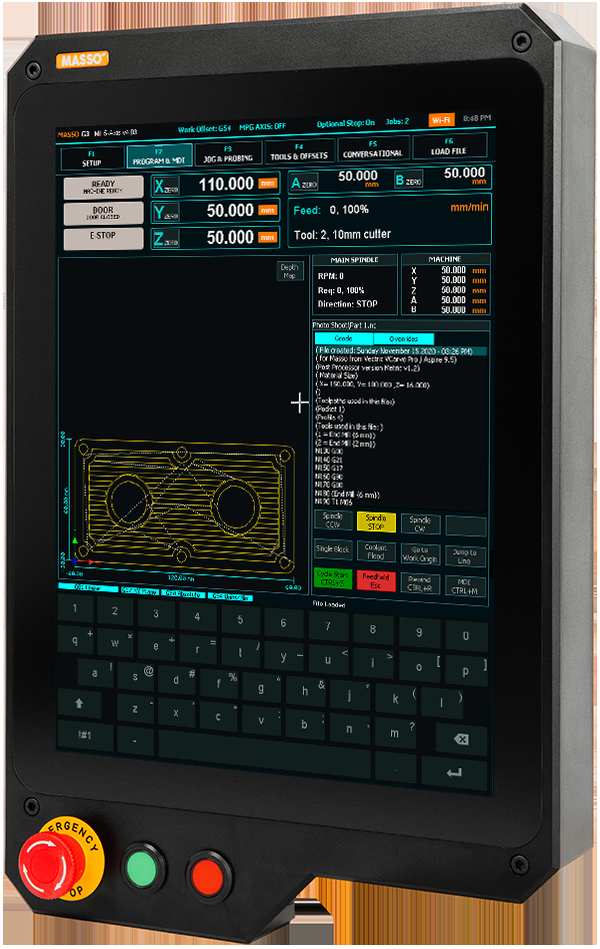

| Masso Controller |

| Billeted Aluminum Gantry Support Posts |

| 3HP air cooled spindle |

| Fuling VFD |

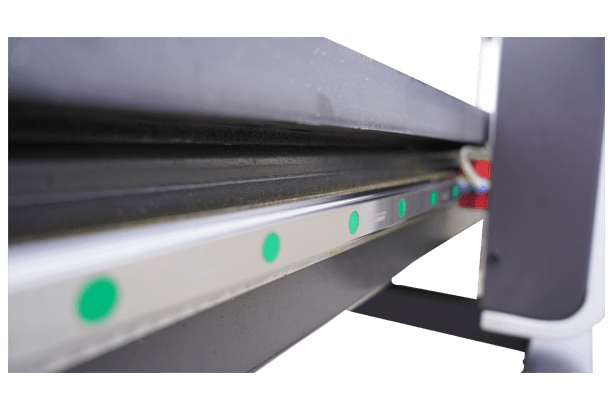

| LED Light Bar |

| T-slot/Vacuum combination table |

| High-performance Leadshine stepper motors |

| Detachable Electrical Cabinet |

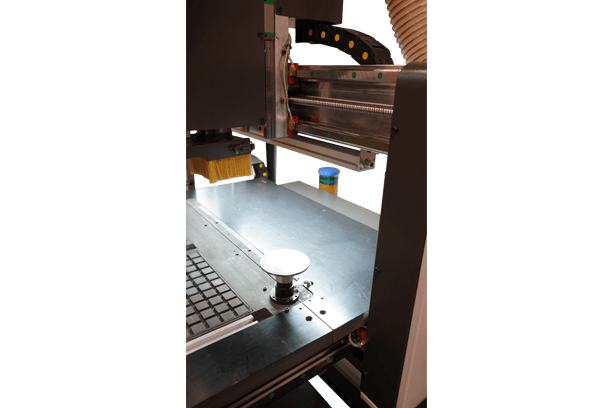

| Fixed Tool Calibrator |

| Mobile Tool Calibrator |

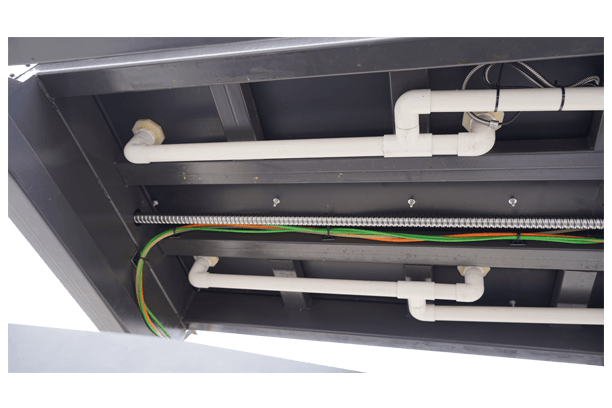

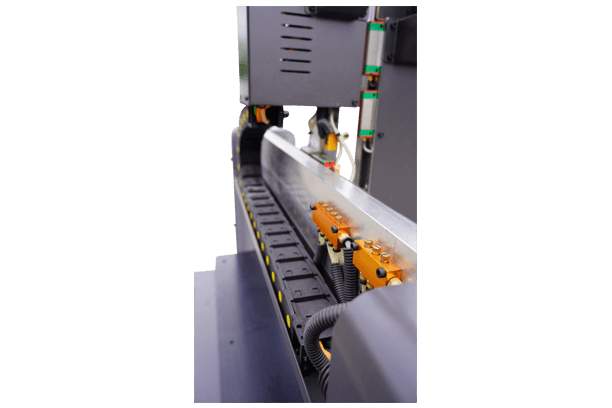

| Centralized Lubrication |

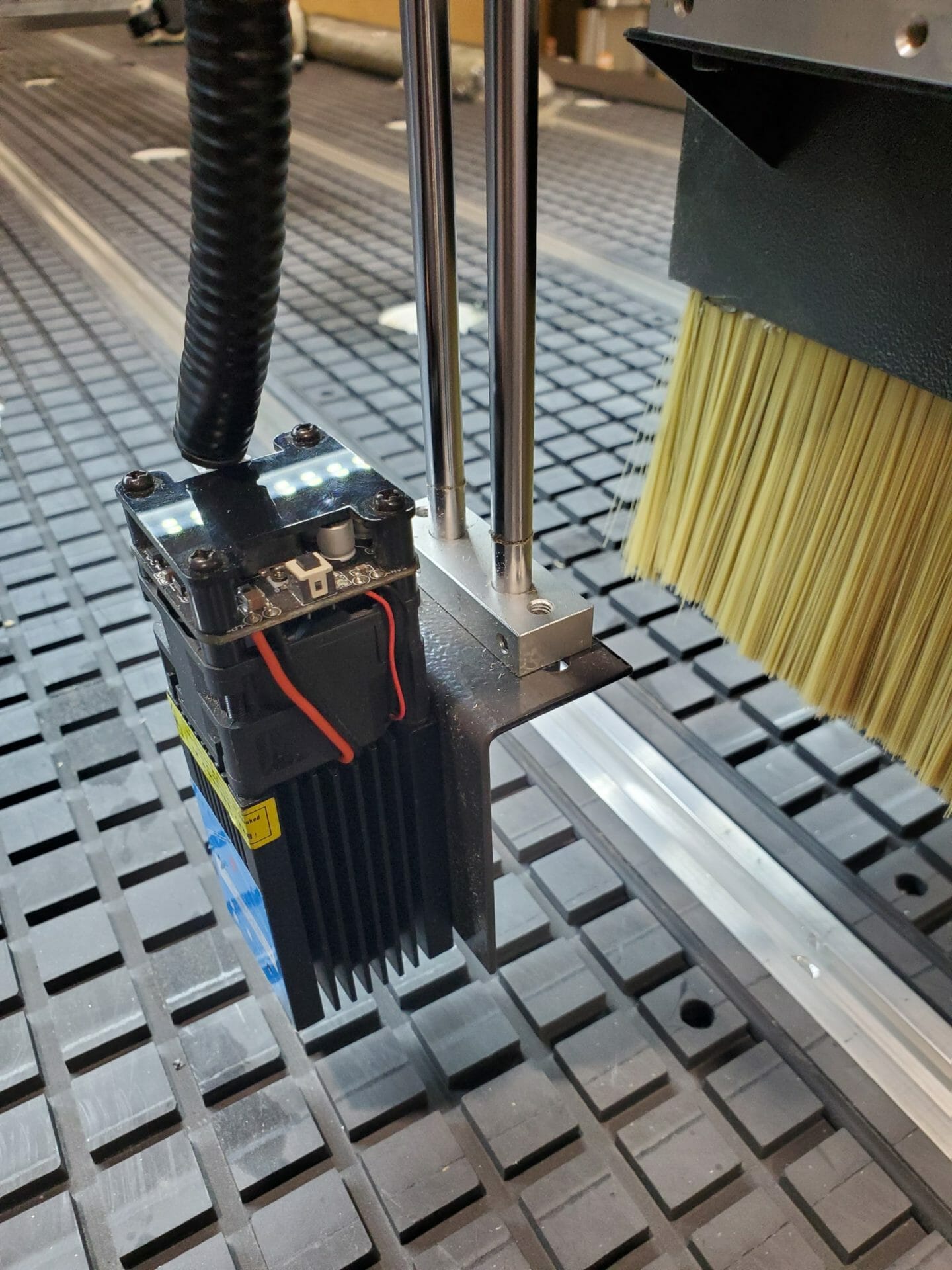

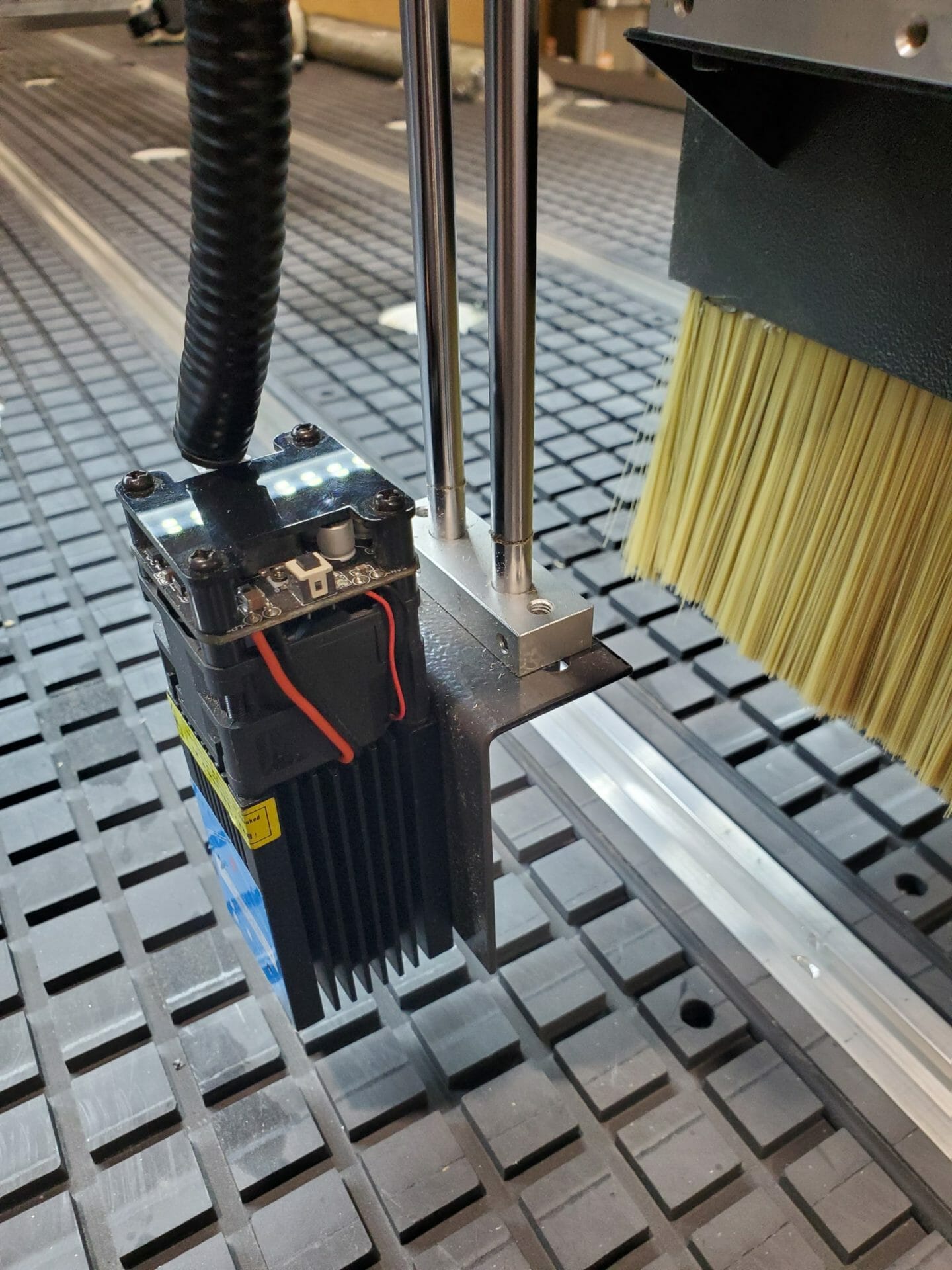

| Easy Clip Dust Boot |

| Vacuum Pump Control |

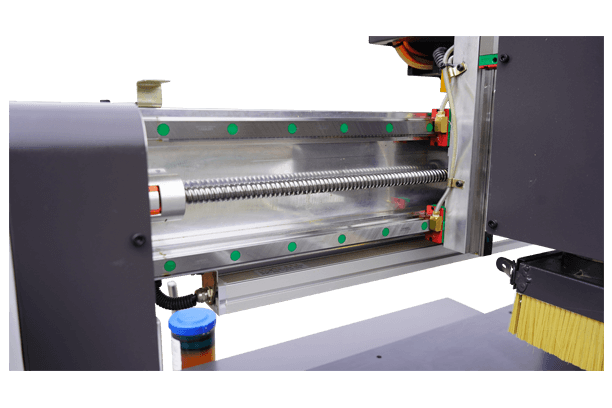

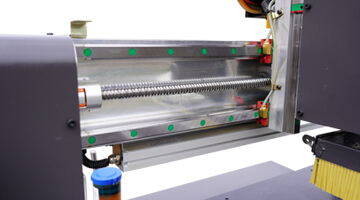

| TBI Ballscrew |

| Hiwin Linear Guides |

Optional Product Features

| Coolubricator JR™ Lubrication system’s durable, 16 oz. (0.5 L) vented reservoir. An accessorial add on of a diode laser is useful for a variety of cuts or engravings. Fast and easy engraving on polished and anodized aluminum, steel, stainless steel without engraving paste, copper & brass. Laser engraving on plywood or balsamic birch, leather, glass,acrylic, stone,plastics. The Coolubricator JR™ combines lubricant and air in a co-axial nozzle tip. The oil mist lubrication system keeps atomization and distribution of the liquid consistent regardless of the hose length. Plastic 12 in. nozzle is coupled with 5 ft. Co-Axial hose. A heavy-duty magnetic base at the hose/nozzle connection of the oil mist lubrication system makes it easier to relocate and position the nozzle at the friction points. Typically used for the maching non ferrous metals to prevent welding and increase tool longevity. |

| The 9 watt laser diode is 445 nm lubrication system’s durable, 16 oz. (0.5 L) vented reservoir. An accessorial add on of a diode laser is useful for a variety of cuts or engravings. Fast and easy engraving on polished and anodized aluminum, steel, stainless steel without engraving paste, copper & brass. Laser engraving on plywood or balsamic birch, leather, glass,acrylic, stone,plastics. The Coolubricator JR™ combines lubricant and air in a co-axial nozzle tip. The oil mist lubrication system keeps atomization and distribution of the liquid consistent regardless of the hose length. Plastic 12 in. nozzle is coupled with 5 ft. Co-Axial hose. A heavy-duty magnetic base at the hose/nozzle connection of the oil mist lubrication system makes it easier to relocate and position the nozzle at the friction points. Typically used for the maching non ferrous metals to prevent welding and increase tool longevity. |

| Donek Tools D1 Drag Knife The Donek Tools Drag Knife for CNC routerss can be used to cut almost anything you would cut with a utility knife, but with the speed and precision of a CNC router. The Donek Drag Knife fits into your CNC router or spindle collet, making it a universal fit for almost any CNC router available. The tools were designed to use a utility knife blade (which can be purchased at just about any hardware store) which dramatically reduces the cost of consumable blades. Fits in 1/2in Collet. Common materials that are used with this tool are wood veneer for inlay/marquetry artwork, leather, carbon fiber pre-preg laminates for aerospace, military, and automotive components, cardboard for custom packaging, and much more. |

| Donek Creasing Attachment Donek CNC router creasing attachment can be used to crease cardboard, foam and similar materials.

|

| Mill Foam Matt Mill foam mat is ideal for wood, plastics or aluminum that is uneven or wavey. The purpose of this product is to assist in creating a vacuum seal between your spoilboard and the workpiece. This product is made in Germany and can be used for a long period of time if you do not cut all the way through it. Please note the milling foam matt is sold in 60×12” width x length at a 3mm thickness. |

| Single Phase Vacuum Pump Single phase vacuum pumps work for majority of our clients end use application. |

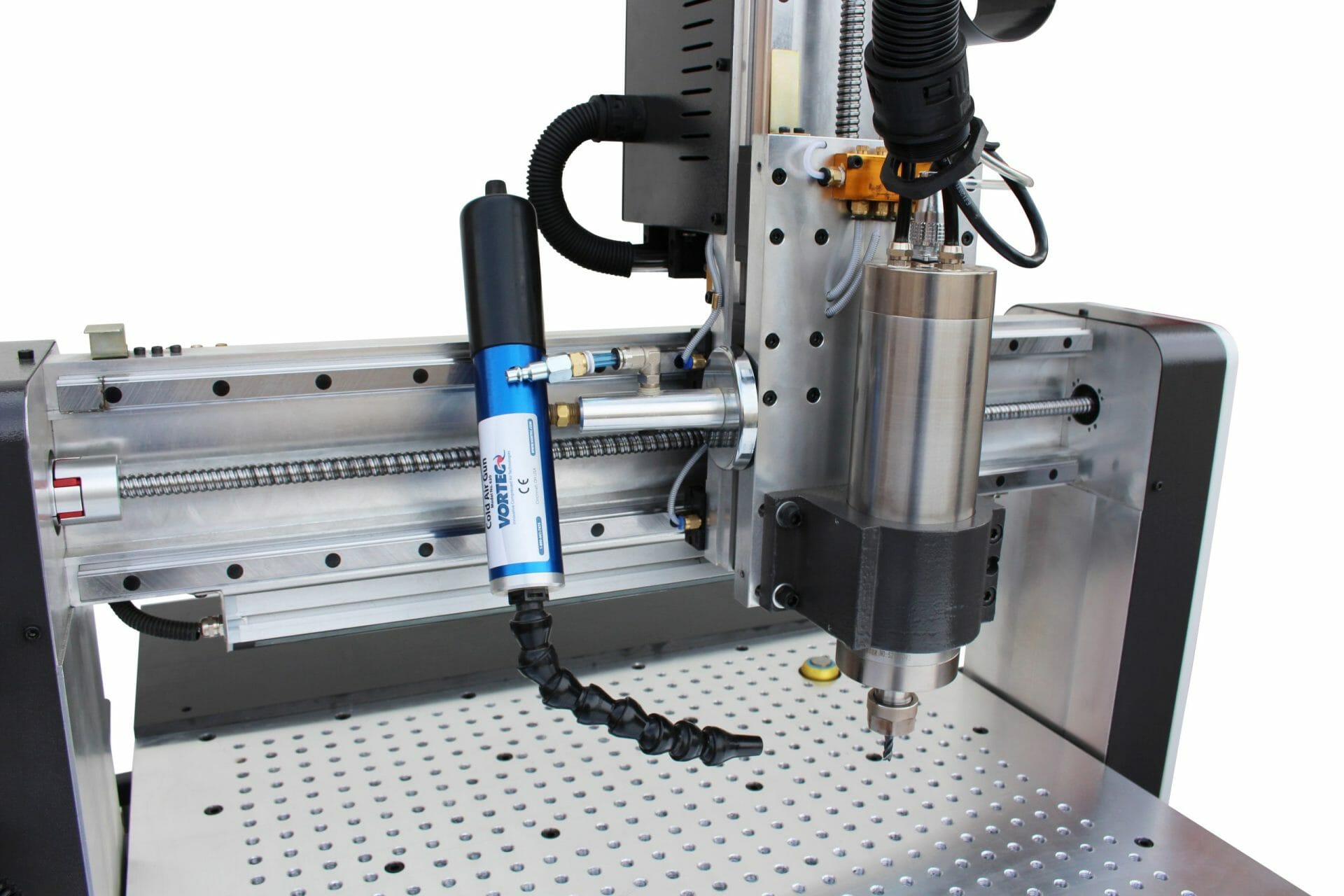

| Vortec Mini Cold Air Gun Cold Air Guns use vortex tube technology and filtered compressed air to produce sub-freezing air as low as -30 deg F for numerous industrial spot cooling applications. With no moving parts to wear out, Cold Air Guns require no electricity at the target, just a compressed air source. Cold Air Guns use vortex tube technology and filtered compressed air to produce sub-freezing air as low as -30 deg F for numerous industrial spot cooling applications. With no moving parts to wear out, Cold Air Guns require no electricity at the target, just a compressed air source. |

| Rotary Lathe 1 Piece The one piece CNC router rotary lathe is extremely robust and heavy duty. This rotary lathe is typically use with a masso controller to utlize the interpolating 4 axis feature. You can use a lathe to shape, engrave or mill wood, plastics and the like. |

| two piece rotary lathe The two piece CNC router rotary lathe is meant for a light for medium duty workload. |

- mm

- inch

Specification

Physical Features

| Machining Bed Width/Length | 610mm x 915mm |

| Z Travel | 175mm |

| Gantry Height Clearance Standard | 203mm |

| Gantry Height Clearance Option | 304mm |

| Table Top | T-Slot/Vacuum Combo Table |

| Location Pins | N/A |

| Centralized Lubrication | Included |

| Leveleing Castors | N/A |

| Auto Tool Touch off-Mobile | Included |

| Auto Tool Touch off-Fixed Position | Yes/With Masso |

| Machine Footprint | 1390mmx 942mm x 701mm 615mm |

| Electrical Cabinet Size | 676 mm x 500 mm x 250 mm |

| Net Weight | 1050 lbs/480 kg |

| Gross Weight | 1168 lbs/530 kg |

Power

| Voltage | 220V Single phase 60Hz |

| Optional Voltage | 208V three phase |

| Rated Power Requirement with vacuum pump | 25 AMP |

| Power Requirement without vacuum pump | 16 AMP |

Controller

| Interface | MASSO G3 |

| Type | Touch Screen |

| Screen Size | 15 in/38.1 cm |

| Touch Screen | Yes |

| Operating System | Dedicated |

| Inputs | USB |

| MPG Handwheel | Included |

| Wifi File Transfer | Included |

Standard Spindle

| Model | Generic |

| Power | 2.2 KW / 3 HP |

| Max Speed | 24000 RPM |

| Collet Size | ER 20 ISO 20 |

| Spindle Upgrades | N/A |

| Variable Frequency Drive | Delta VFD B - 22E21VFD022E21A |

| Cooling System | Air Cooled |

| Tool Change Type | Manual |

| Tool Holder Positions | N/A |

Drive System

| Motor | Yako YKC2405M on XY and YKC2405MS on Z |

| Type | Micro Stepper NEMA 34 |

| Transmission | X and Y axis - TBI Ball Scew Drive/Z axis - TBI Ball Screw Drive/Hiwin Linear Guid rails for all axes |

Speed

| Rapid Speed XY | 300 IPM |

| Rapid Speed Z | 120 IPM |

| Max Cutting Speed | 300 IPM |

Tool Calibrator

| Fixed Position | Available |

| Portable | Included |

Accuracy

| Positioning | 0.2 mm |

| Repositioning | 0.05 mm |

Physical Features

| Machining Bed Width/Length | 24in x 36in |

| Z Travel | 6.9in |

| Gantry Height Clearance Standard | 8.0in |

| Gantry Height Clearance Option | 12.0in |

| Table Top | T-Slot/Vacuum Combo Table |

| Location Pins | N/A |

| Centralized Lubrication | Included |

| Leveleing Castors | N/A |

| Auto Tool Touch off-Mobile | Included |

| Auto Tool Touch off-Fixed Position | Yes/With Masso |

| Machine Footprint | 54.7in x 37.1in x 27.6in 24.2in |

| Electrical Cabinet Size | 26.5in x 19.7in x 9.85in |

| Net Weight | 1050 lbs/480 kg |

| Gross Weight | 1168 lbs/530 kg |

Power

| Voltage | 220V Single phase 60Hz |

| Optional Voltage | 208V three phase |

| Rated Power Requirement with vacuum pump | 25 AMP |

| Power Requirement without vacuum pump | 16 AMP |

Controller

| Interface | MASSO G3 |

| Type | Touch Screen |

| Screen Size | 15 in/38.1 cm |

| Touch Screen | Yes |

| Operating System | Dedicated |

| Inputs | USB |

| MPG Handwheel | Included |

| Wifi File Transfer | Included |

Standard Spindle

| Model | Generic |

| Power | 2.2 KW / 3 HP |

| Max Speed | 24000 RPM |

| Collet Size | ER 20 ISO 20 |

| Spindle Upgrades | N/A |

| Variable Frequency Drive | Delta VFD B - 22E21VFD022E21A |

| Cooling System | Air Cooled |

| Tool Change Type | Manual |

| Tool Holder Positions | N/A |

Drive System

| Motor | Yako YKC2405M on XY and YKC2405MS on Z |

| Type | Micro Stepper NEMA 34 |

| Transmission | X and Y axis - TBI Ball Scew Drive/Z axis - TBI Ball Screw Drive/Hiwin Linear Guid rails for all axes |

Speed

| Rapid Speed XY | 300 IPM |

| Rapid Speed Z | 120 IPM |

| Max Cutting Speed | 300 IPM |

Tool Calibrator

| Fixed Position | Available |

| Portable | Included |

Accuracy

| Positioning | 0.0079 in |

| Repositioning | 0.0020 in |