CanCam X540

Vertical machining center, VMC Machine, VMC Canada

Description

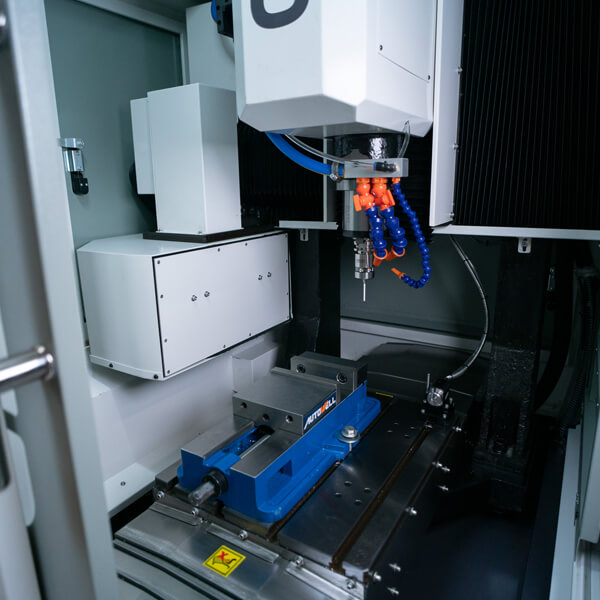

Discover the precision and efficiency of the CanCam X540, a compact CNC milling machine engineered to deliver big performance in a small footprint. Designed for workshops where space and budget matter, the X540 combines industrial-grade rigidity with an impressive feature set—making it the ideal entry into professional CNC machining without compromise.

Despite its space-saving design, the X540 is built with a rigid frame and structural integrity that ensures exceptional machining accuracy and stability. Drawing just 5.2kW of power, the machine operates effortlessly on a standard 40 AMP breaker, making it perfect for smaller facilities or single-phase applications.

At the heart of the X540 is the reliable GSK218MC-H controller, known for its intuitive interface and dependable performance. This robust control system enables seamless programming and high-precision execution for even complex machining tasks.

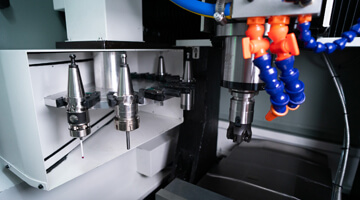

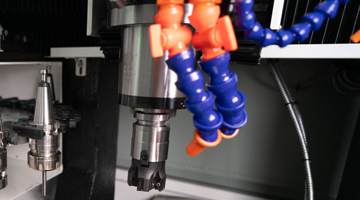

Equipped with a Lichuan 3kW (4HP) spindle reaching speeds up to 9000 RPM, the X540 delivers the torque and speed required for demanding applications like milling, drilling, and engraving. Its 8-position automatic tool changer uses a compact disc-type magazine to minimize tool change time and maximize workflow efficiency.

Key Features:

Space Saving Design – Minimal footprint without sacrificing performance

Power-Efficient – Runs on a 40 AMP breaker with a 5.2kW power draw

GSK218MC-H Controller – Reliable and easy to program for advanced operations

Lichuan 3kW / 4HP Spindle – Max speed 9000 RPM with excellent torque and precision

8-Tool ATC Disc Changer – Rapid tool swaps to reduce downtime

Cost-Effective CNC Milling Solution – Professional-grade results at a budget-friendly price

Whether you’re producing parts in a tight production space or just entering CNC manufacturing, the CanCam X540 delivers a powerful blend of performance, affordability, and reliability. It’s the perfect machine to scale your productivity without scaling your costs.

Invest in the CanCam X540 today where compact design meets industrial capability.

Product Features

| Single phase or 3 phase power This can be outfitted as a Single phase VMC or a 3 Phase VMC. All on a 40amp breaker for minimal power draw. |

| Durable Iron Casting And High Quality Components A cast iron gantry and bed creates an extra rigid setup with a minimal footprint. The high quality transmission components make this machine hold tight tolerances and a machine you can demand on. |

| Tool Changer Equipped with a 8 tool location disc ATC Magazine, you can be ready with any tool for your production needs. The Servo motor driven automatic tool changer guarantees a smooth and rapid tool change process.

|

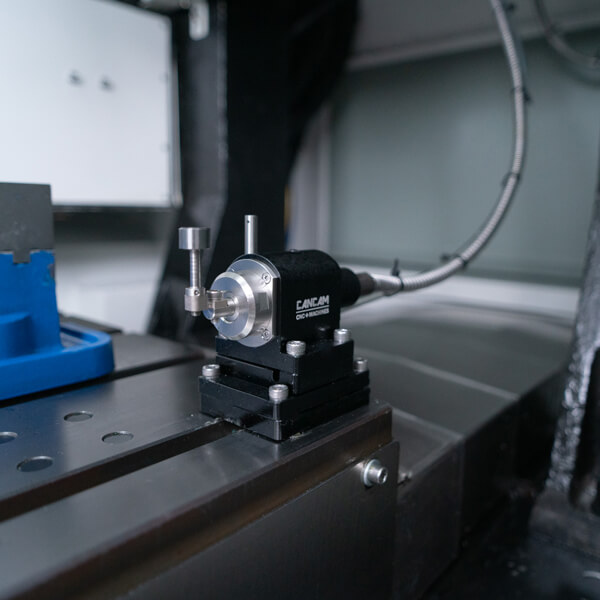

| Tool Setter Our 3D Touch Trigger Tool Setter is designed to expedite the measuring process and enhance the performance of our vertical milling machines. It focuses on delivering rapid measurements of tool length and diameter, thereby streamlining your operations and significantly cutting down setup times. You can expect an impressive repeatability of 1.00 μm 2σ, ensuring precise measurements every time. This comes STANDARD on our CanCam vertical milling machines.

|

| Touch Probe The probe is designed to improve machine tool manufacturing efficiency, reduce machine downtime awaiting first-off inspection results, and mitigate the impact of fixture and incoming material errors. This touch probe uses the kinematic resistive principle, a proven technology for stable, long-term operation. It provides highly precise measurements. This comes STANDARD on our CanCam vertical milling machines.

|

| Coolant nozzles The numerous coolant nozzles in our design offer notable enhancements to machining efficiency, including superior surface finish, optimized chip evacuation, and improved cooling of the tool.

|

| Electrical Cabinet The electronic components of the machine, which are conveniently accessible, are sourced exclusively from industry-leading manufacturers. These include but are not limited to Lovato, Schneider, Fanuc, and Delta, thereby ensuring high performance and reliability.

|

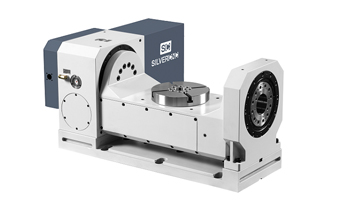

| 4th 5th axis We have partnered with SILVERCNC to bring to you some of the best 4 and 5 axis units money can buy but all at an actually affordable cost. With amazing tolerances and smooth operation, these 4th and 5th axis units will ensure you hold the tight tolerances you need.

|

- mm

- inch

Specification

Physical Features

| Machining Bed Width/Length | 500mm x 400mm |

| X Axis Travel | 500 mm |

| Y Axis Travel | 400mm |

| Max. Table load | 200kg |

| Spindle nose to table | 150 - 350mm |

| X/ Y/ Z axis Rapid Traverse | 30 m/min |

| Table Top | T - Slot Cast Iron |

| Tool Capacity | 8 |

| Automatic Lubrication | Included |

| Leveling Feet | Included |

| Touch Probe | Infrared Touch Probe |

| Auto Tool Touch off-Fixed Position | Included |

| Machine Footprint | 1350×1350×2050mm |

| Net Weight | 4188 lbs/1900 kg |

| Gross Weight | 4519 lbs/2050 kg |

Power

| Single Phase Voltage | 5.2Kw @ 220V Single phase (3Kw Spindle) |

Controller

| Interface | GSK GSK218MC-H |

| Type | Industrial |

| Screen Size | 203 mm LED |

| Operating System | Dedicated |

| Inputs | USB |

| MPG Handwheel | Included |

| Ethernet | Included |

| Controller Upgrade Option | N/A |

Standard Spindle

| Model | LICHUAN |

| Power | 3Kw / 4HP |

| Max Speed | 9000 RPM |

| Tool Holder | BT30 |

| Tool Change Type | Automatic |

| Tool Holder Positions | 8 |

Drive System

| Motor | GSK Absolute Servos |

| Transmission | X Y Z axis - TAIWAN ballscrews and linear guides |

Speed

| Rapid Speed XY | 1181 IPM |

| Rapid Speed Z | 984 IPM |

Tool Calibrator

| Fixed Position | Included |

| Touch Probe | Included |

Accuracy

| Repeatability | 0.01 mm |

Physical Features

| Machining Bed Width/Length | 19.69 x 15.75 In |

| X Axis Travel | 19.685 In |

| Y Axis Travel | 15.748 In |

| Max. Table load | 200kg |

| Spindle nose to table | 5.905 - 13.779 In |

| X/ Y/ Z axis Rapid Traverse | 1.181 in/min |

| Table Top | T - Slot Cast Iron |

| Tool Capacity | 8 |

| Automatic Lubrication | Included |

| Leveling Feet | Included |

| Touch Probe | Infrared Touch Probe |

| Auto Tool Touch off-Fixed Position | Included |

| Machine Footprint | 53.149×53.149×80.708in |

| Net Weight | 4188 lbs/1900 kg |

| Gross Weight | 4519 lbs/2050 kg |

Power

| Single Phase Voltage | 5.2Kw @ 220V Single phase (3Kw Spindle) |

Controller

| Interface | GSK GSK218MC-H |

| Type | Industrial |

| Screen Size | 203 mm LED |

| Operating System | Dedicated |

| Inputs | USB |

| MPG Handwheel | Included |

| Ethernet | Included |

| Controller Upgrade Option | Siemens |

Standard Spindle

| Model | LICHUAN |

| Power | 3Kw / 4HP |

| Max Speed | 9000 RPM |

| Tool Holder | BT30 |

| Tool Change Type | Automatic |

| Tool Holder Positions | 8 |

Drive System

| Motor | GSK Absolute Servos |

| Transmission | X Y Z axis - TAIWAN ballscrews and linear guides |

Speed

| Rapid Speed XY | 1181 IPM |

| Rapid Speed Z | 984 IPM |

Tool Calibrator

| Fixed Position | Included |

| Touch Probe | Included |

Accuracy

| Repeatability | 0.0004 In |