Effective Maintenance of CNC Machines

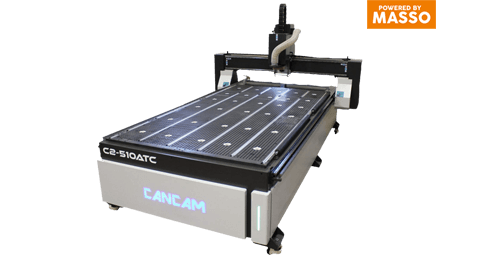

Proper maintenance of wood or plastic CNC routers is important to ensure that they function properly and remain functional for a long period of time. Regular maintenance becomes all the more important as the machine is usually put to use in an environment filled with saw dust, which spreads quickly. Following simple steps on a regular basis, when the machine is running and when it is idle, can enhance its performance and extend its life.

Daily Care

Cleaning the CNC router only once in a week of fortnight is not going to help. When the machine is used every day, it has to be cleaned on a daily basis. To begin with, make sure that the coolant of the machine is clean and any chips on it are removed each day. Ensure that the bottom pan, the way covers, the tool changer and other parts of the machine are free of any chips. The spindle taper should be cleaned with a clean cloth and be slightly oiled before the machine is put aside after use.

The insides of the wood CNC router, especially the chip drawer should also be cleaned every day. Otherwise, the chip buildup in the drawer can restrict the coolant from getting to the pump, resulting on low coolant pressure. This in turn will generate heat that can damage the tools. A simple way to prevent chips from hindering the cutting process is to keep cleaning the table as and when needed.

Lubrication

The ball bearings, screws and other rolling parts of the CNC router should be lubricated regularly, as and when needed. Make sure that the oil used for lubrication of the machine components is clean and nit used. After oiling, make sure that the other parts like the rack, the gear etc. are clean and free of dirt.

Check the oil reservoir and fill it up when needed. Warm up the machine for a few minutes before you start using for the first time during the day. This allows the oil to be distributed evenly through the components and allows for smooth function of the machine.

Tips on Proper Usage

To ensure proper functioning of the machine, you also need to keep in mind a few tips on how to handle it. Make sure that the machine is lubricated at all times. Avoid using the spindle for more than 24 hours at a stretch, and let it stay idle for at least an hour every day. When cleaning the exterior of the machine, be sure to clean it with a cloth a little water, but not solvents of any kind.

In addition to all these, ensure that the transmission components, the electrical and other parts of the machine are thoroughly checked by an experienced technician once every year.